The KITZ Group offers a lineup of over 90,000 types of products trusted by customers in and out of Japan for their top quality. The KITZ Group boasts an expansive brand portfolio. It includes the KITZ brand offered by KITZ Corp., an all-round valve player; the TOYO brand known for their outstanding presence in the building construction business; the SGS brand recognized in the water supply and sewage system fields; and the KITZ SCT brand, well known among semiconductor manufacturers; the Perrin brand (Perrin GmbH) in Germany.

Product From KITZ

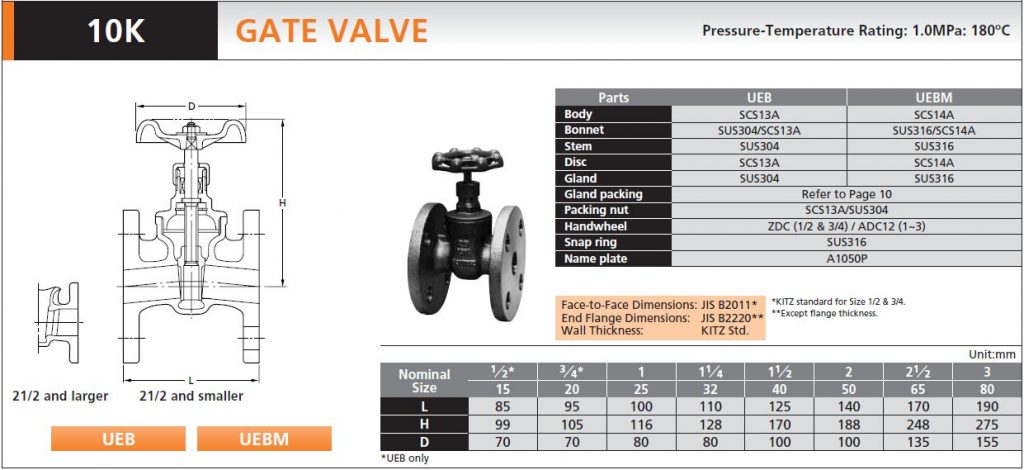

Gate Valve

Gate valves are characterised as having either a rising or a nonrising stem. Rising stems provide a visual indication of valve position because the stem is attached to the gate such that the gate and stem rise and lower together as the valve is operated. Nonrising stem valves may have a pointer threaded onto the upper end of the stem to indicate valve position, since the gate travels up or down the stem on the threads without raising or lowering the stem. Nonrising stems are used underground or where vertical space is limited. Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

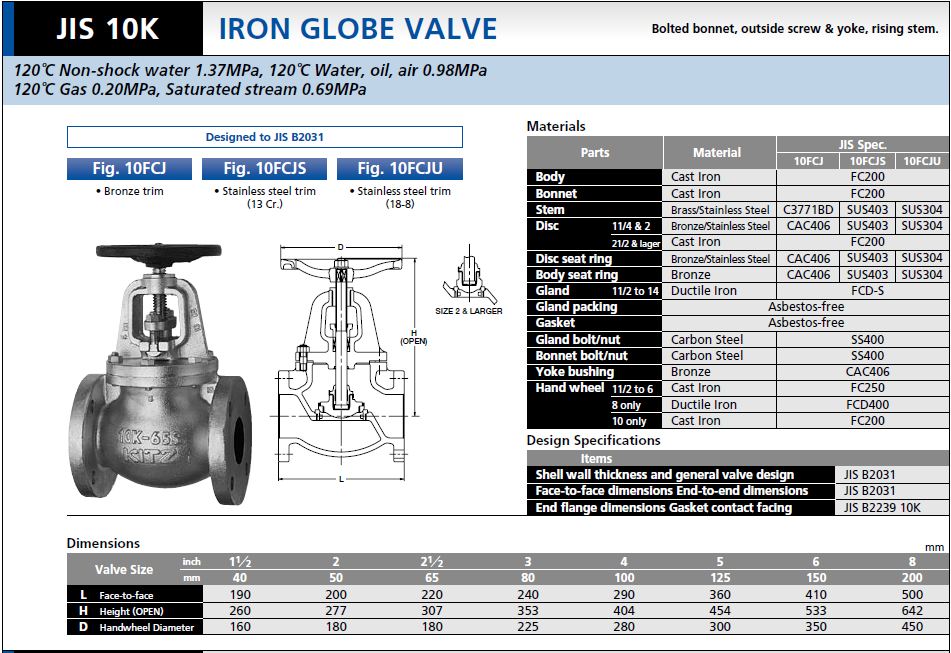

Globe Valve

A globe valve, different from ball valve, is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body.

Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug can be screwed in to close (or shut) the valve. The plug is also called a disc or disk. In globe valves, the plug is connected to a stem which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuatorassembly.

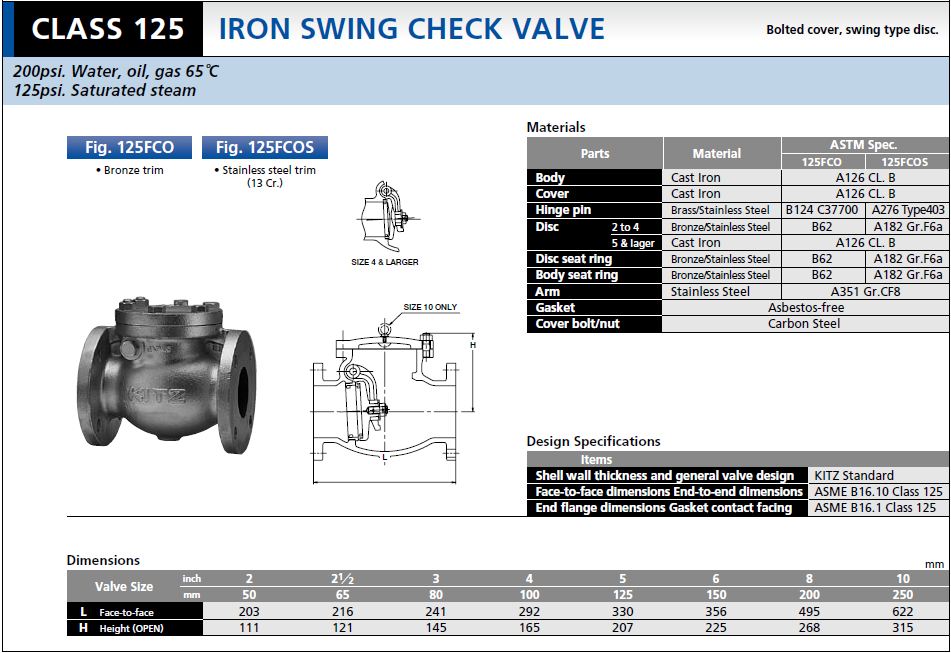

Check Valve

A check valve, clack valve, non-return valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, or inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal.

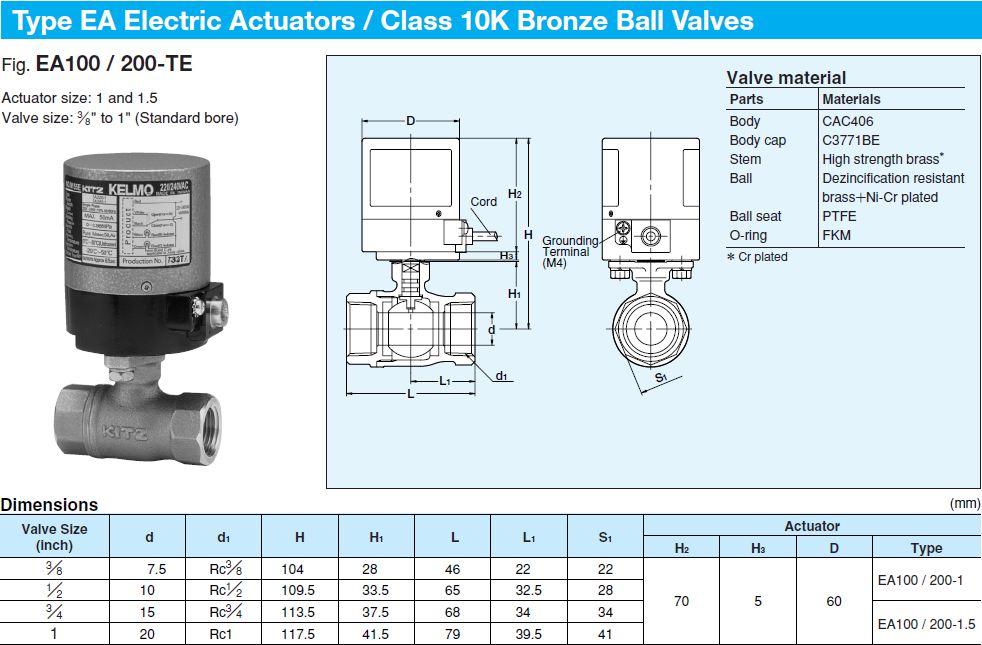

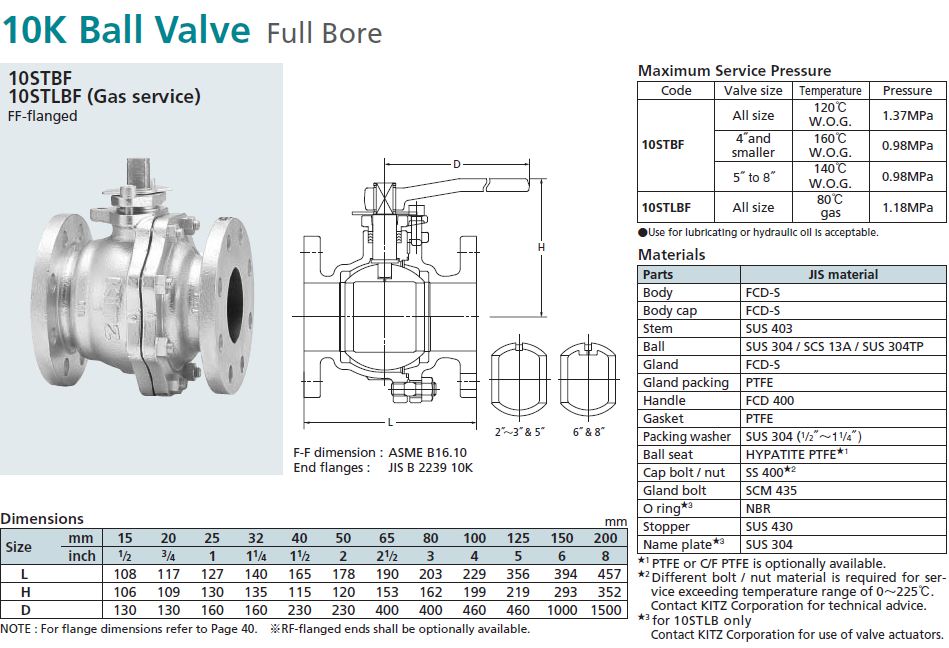

Ball Valve

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball (called a “floating ball”) to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status.

Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff applications, where they are often preferred to gates and globe valves, but they lack their fine control in throttling applications.

The ball valve’s ease of operation, repair, and versatility lend it to extensive industrial use, supporting pressures up to 1000 bar and temperatures up to 752°F (500°C), depending on design and materials used. Sizes typically range from 0.2 to 48 inches (0.5 cm to 121 cm). Valve bodies are made of metal, plastic, or metal with a ceramic; floating balls are often chrome plated for durability.

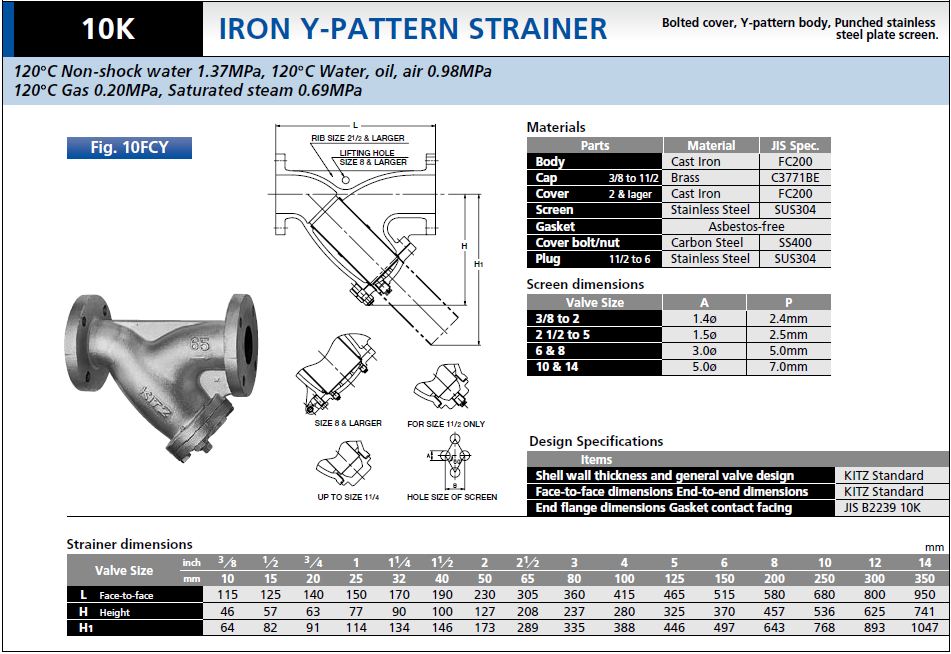

Strainer

When debris, such as scale, rust and other foreign matter mixes with the water, oil, gas, air, steam or other media and is allowed to flow through a pipeline, it can become the cause of damage to the line’s valve seats, resulting in shortened valve life, not to mention equipment malfunction and damage.

Strainers separate and remove the solids suspended in fluids, protecting equipment from their harmful effects. Each strainer incorporates a screen to filter suspended solids and is designed so that collected solids can be disposed of and the filter cleaned without having to be removed from the line.

Strainers can be classified into two main types according to their shape: Y-type and U-type. KITZ offers both a Y-type strainer that provides relatively low resistance to fluids and a compact shape, requiring less installation space, and the U-type that can be added plumbed into plant equipment.

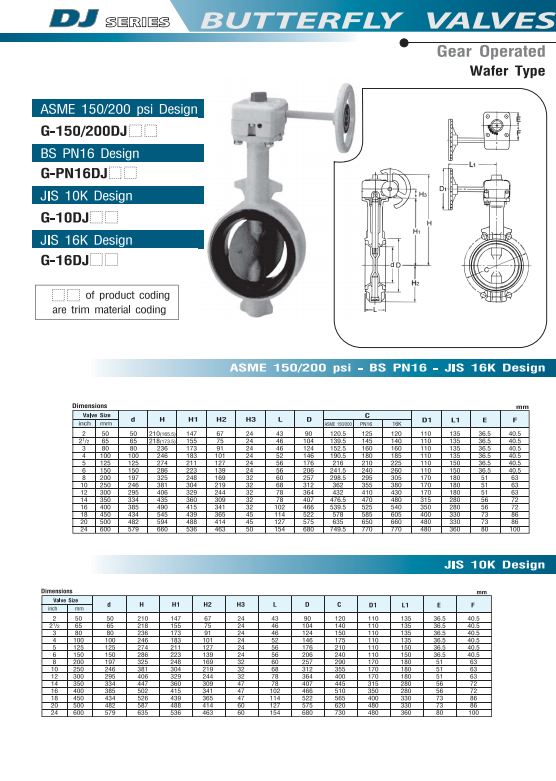

Butterfly Valve

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe; passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so a pressure drop is always induced in the flow, regardless of valve position.

Actuator

An actuator is a type of motor that is responsible for moving or controlling a mechanism or system.

It is operated by a source of energy, typically electric current, hydraulic fluid pressure, or pneumatic pressure, and converts that energy into motion.

An actuator is the mechanism by which a control system acts upon an environment. The control system can be simple (a fixed mechanical or electronic system), software-based (e.g. a printer driver, robot control system), a human, or any other input.